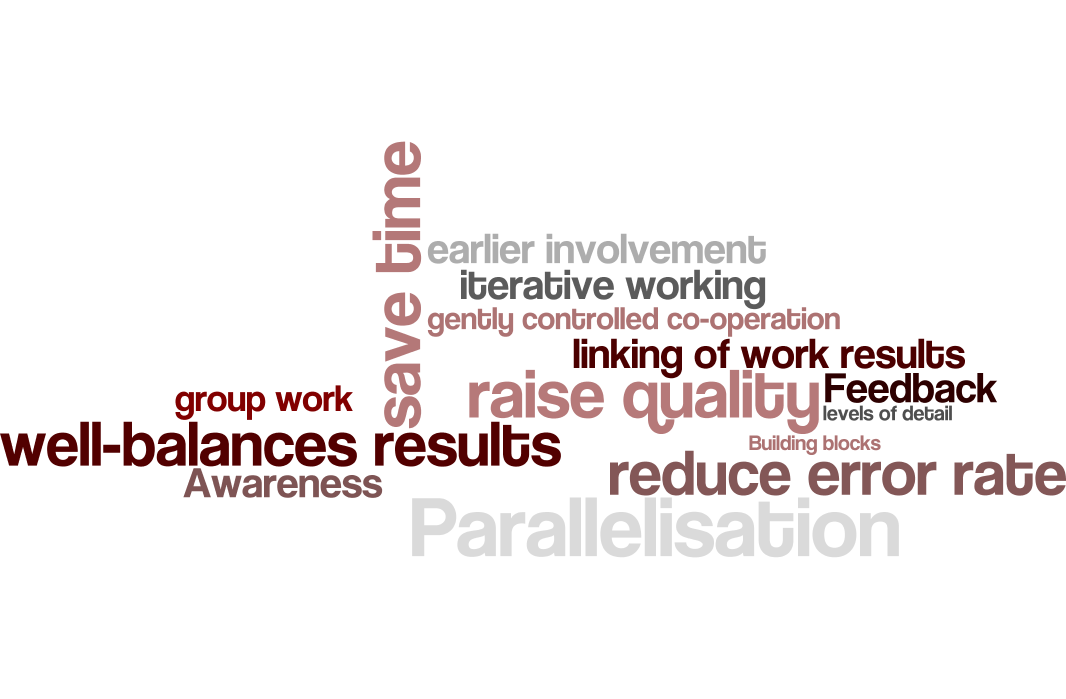

Many of today's strictly sequentially executed intellectual work steps can be partially parallelised.

Parallelisation gets possible through the deployment of predefined building blocks and the detailled, process step-spanning linking of work results.